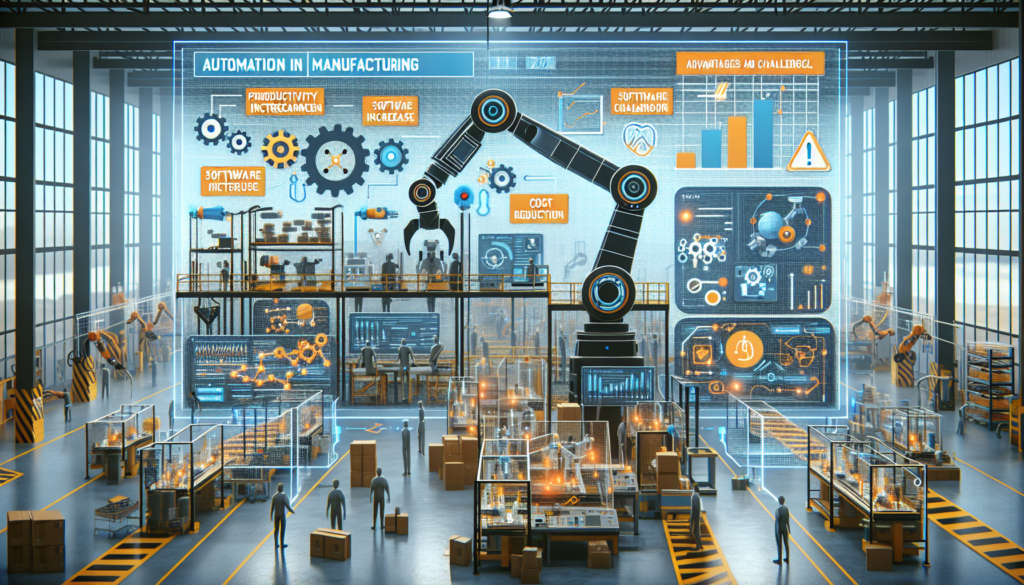

In the last decade, the manufacturing industry has undergone a significant transformation, driven by advances in automation and robotization. These innovations are redefining the ways in which companies design, produce, and distribute their products. Automation brings a series of tangible benefits, including increased efficiency, cost reduction, and improved quality, but it also poses significant challenges that require careful consideration and strategic response. This article provides a detailed analysis of these aspects, offering a comprehensive look at the current state of automation in manufacturing and its potential future trajectories.

Innovations in Industrial Automation

Starting from the basis of industrial automation theories, it is recognized that the integration of cyber-physical systems (CPS) in manufacturing environments has revolutionized the productive paradigm. CPS combine elements of hardware and software with data analytics and internet connectivity (IoT), enabling real-time decision-making based on data with great precision.

Advanced Manufacturing Systems

Collaborative Robotics

Collaborative robotics (cobots) is a significant advancement that allows safe interaction between human workers and robots in the workspace. These robots are designed to work hand in hand with humans, complementing their skills and allowing for greater flexibility and adaptability on the production line.

3D Printing and Additive Manufacturing

Additive manufacturing, particularly 3D printing, is enabling the production of complex components with geometries that would be difficult or impossible to achieve with traditional manufacturing methods. This technology offers possibilities for massive customization and a significant reduction in material waste.

Artificial Intelligence and Machine Learning

Artificial intelligence (AI) and machine learning are endowing machines with abilities to optimize processes, predict maintenance, and adapt to changes in production patterns, resulting in much smarter and autonomous manufacturing systems.

Advanced Control and Monitoring Systems

Advances in sensors and control systems allow constant monitoring of operations and a rapid response to potential faults or inefficiencies, thus ensuring a greater consistency in the quality of the final product.

Impact of Automation on Productive Efficiency

The implementation of automation in manufacturing has a direct impact on the productive efficiency of the company. It results in lower downtime thanks to predictive maintenance and continuous operations that surpass the limits of the human workday. Additionally, automation can lead to an improvement in the consistency and precision of manufactured products, increasing the competitiveness of the organization in the market.

Case studies reveal that companies that have adopted automation technologies report significant advances in their capacity to respond to market demand and adapt to rapid changes in consumer preferences.

Challenges Presented by Manufacturing Automation

The path to full automation is not without obstacles. Ethical and social issues, such as the impact on employment and the need to retrain the workforce, are critical aspects that organizations must address with inclusive policies and educational programs.

Initial Investment and ROI

One of the main challenges for small and medium-sized enterprises (SMEs) is the initial investment required for the adoption of automated technologies. The return on investment (ROI) can be difficult to calculate given the rapid evolution of these technologies, which requires careful analysis of the anticipated lifecycle of automation solutions.

Cybersecurity

Cybersecurity is another point of concern due to the inherent interconnectivity of automated systems. The increased potential access points for cyber attacks require robust security solutions and incident response protocols.

Integration and Compatibility

The integration of new systems with existing infrastructure and the issues of compatibility between different technologies and platforms are technical challenges that demand detailed planning and the development of industry standards.

Future Projection and Potential Innovations

Looking forward, the integration of automation systems with other emerging technologies such as quantum computing and nanotechnology could take manufacturing to unprecedented levels of efficiency and customization. The exploration of advanced materials and biofabrication are also fields that will likely influence the development of industrial automation.

Additionally, the focus on sustainable manufacturing environments will stimulate innovation in automation that not only optimizes production but also minimizes environmental footprint.

Conclusion

Automation in manufacturing is a driving force for innovation, efficiency, and economic growth in the modern industry. However, its adoption and development carry significant responsibilities and challenges that must be carefully managed. Organizations that can balance the benefits with the inherent risks will be well-positioned to lead in the new era of advanced manufacturing.